Leica ConX is a cloud solution and web interface to manage, visualise, aggregate and share 3D construction and survey data in real-time for heavy construction projects.

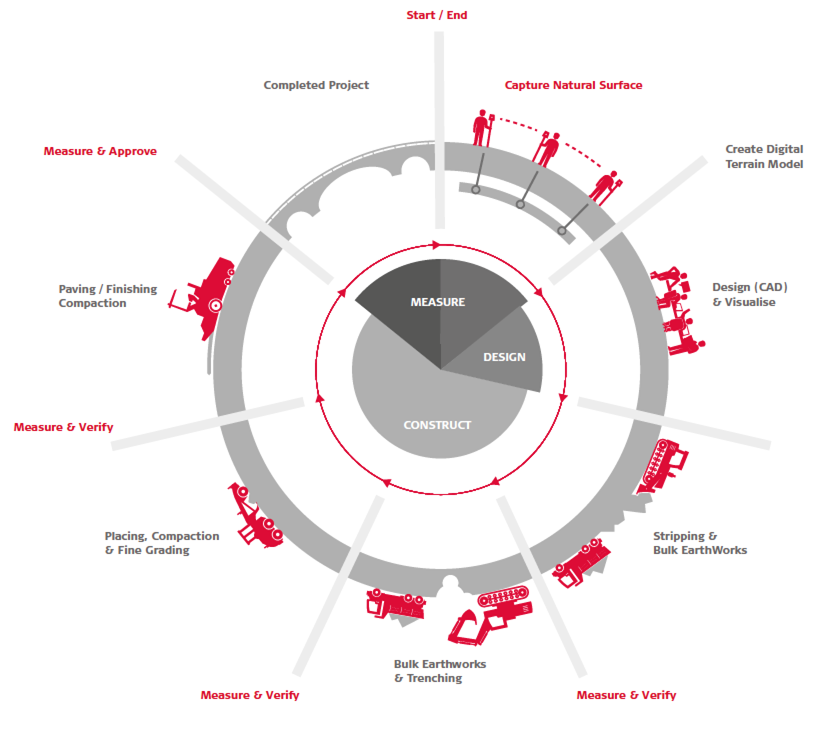

Digitise your construction process with ConX, a cloud-based suite of tools that harmonises and simplifies the data handling and workflow throughout the phases of the construction process.

Significantly improve productivity and reduce rework and delays caused by inefficiencies or errors in 3D construction data. With ConX, users will be able to visualise and validate reference models, project localisations, positioning, survey and constructed as-built data in real-time and without extensive training.

Benefits:

Benefits:

- Visualize and validate data used and generated on-site in 2D and 3D localised on interactive maps to collaborate and communicate with everyone on site

- Share updates and corrections to reference model data in real-time across the project to guarantee transparency and quick reaction to design updates

- Monitor machine control operations remotely by assigning work and providing positioning and reference data to operators and grade checkers ensuring you avoid costly rework and errors

For more information contact Tyler Wright, Machine Control Specialist: 585- 698-0358

Manage, monitor and share construction and survey data in real time, everywhere

Transparency on the job site Machine operators, surveyors and data preparation specialists

are always synchronised with the latest project data from the office and field so work can be carried out effectively, on time and budget. Once work begins, data acquisition and wireless connectivity allow a seamless sharing of as-built data back to the office to be aggregated, visualised and shared for real-time productivity analysis and project reporting. Positioning,reference model and constructed as-built data can be managed from Leica iCON office and Leica Infinity or uploaded directly to ConX to be visualised and shared from the office to the field and back.